Motorized Stages

Guide

Accuracy Verification

Motorized stage accuracy is, in principle, confirmed in compliance with the JIS test code

for machine tools (JIS B 6190).

In addition, all measuring instruments are traceable standard instruments

compliant to the national standard.

| Category | Measurement Item | Device Used | Standards |

|---|---|---|---|

| Linear Stage | Positioning Accuracy | Dynamic Calibrator (HP5529A) |

JIS B 6190 |

| Positional Repeatability | |||

| Lost Motion | |||

| Running Parallelism | Dial Indicator | Company Standard | |

| Pitch/Yaw | Auto Collimator | Company Standard |

It has to be guaranteed that measured values and indicated values are within the specification range of international standard values. In other words, traceability must be ensured. JIS defined this traceability as “the capacity to trace measurement results back to the domestic measurement standards, with the use of measuring instruments that have gone through a sequence of calibrations with high-ranking standards.”

| Category | Measurement Item | Device Used | Standards |

|---|---|---|---|

| Rotation Stage | Positional Repeatability | Rotary Encoder | Company Standard |

| Lost Motion | |||

| Wobble Accuracy | Dial Indicator | Company Standard | |

| Goniometer Stage | Positional Repeatability | Rotary Encoder | Company Standard |

| Lost Motion | |||

| Rotation Center Height | Three Dimensional Instrumentation | Company Standard | |

| Rotation Center Deviation Accuracy |

Accuracy Check in Assembled State

We check accuracy of motorized stages as a single unit.

Regarding the accuracy check in assembled state,

we need to confirm use conditions etc. Contact our International Sales Division separately.

Accuracy Check at Delivery Destination

We cannot conduct accuracy check at delivery destinations.

We will request a check from organizations such

as Japan Quality Assurance Organization as necessary.

Contact our International Sales Division separately

for more information.

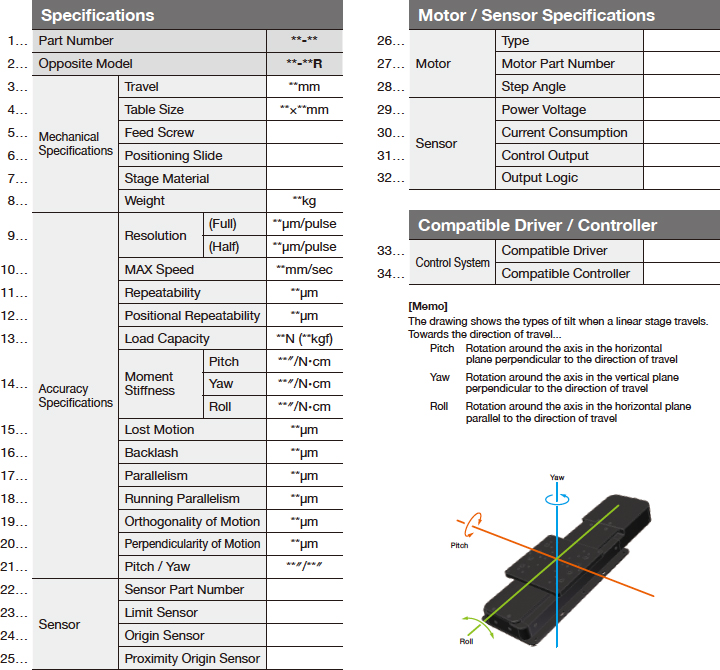

Interpretation of the Specification Table

- Part Number

- Opposite Model

Mechanical Specifications

- Travel

Indicates the full travel.

- Table Size

Size of top table face.

- Feed Screw

* Ball screw

* Precision ground screws - Positioning Slide

* Outer rail structure

* Crossed roller guide - Stage Material

Material used for the product.

- Weight

Self weight of the product.

Accuracy SpecificationsRefer to the accuracy verification page for more information.

-

Resolution (Half)

Travel per pulse for full step

Resolution (Full)Travel per pulse for half step

- MAX Speed

MAX speed of the product (maximum travel speed).

- Positioning Accuracy

Deviation between the measured value and the target value at the positioning point.

- Positional Repeatability

Deviation in stop positions when unidirectional positioning is performed multiple times.

- Load Capacity

Load capacity at the center of the stage

-

Moment Stiffness

Stage strength against a load exerted at a position away from the center of the table top (the table center and the center of gravity of a work does not match).

It indicates the degree of tilt of the table top (″) when 1N load is exerted at the position 1cm away from the center of the stage surfacePitchStiffness in the direction of tilt around the axis in the horizontal plane perpendicular to the direction of travel when moving the stage for full travel.

YawStiffness in the direction of tilt around the axis in the vertical plane perpendicular to the direction of travel when moving the stage for full travel.

RollStiffness in the direction of tilt around the axis in the horizontal plane parallel to the direction of travel when moving the stage for full travel.

- Lost Motion

Deviation between the stop position of forward positioning and that of backward positioning.

- Backlash

Deviation in each direction when a certain load is exerted in forward and backward directions at an arbitrary position on the stage.

- Parallelism

The parallelism of the table fixed on the stage against the base plane.

* Note that it is different from “Running Parallelism”. - Running Parallelism

Displacement in the vertical direction of the table during stage motion along the full travel.

- Orthogonality of Motion

Working displacement in the direction perpendicular to the Y axis when referenced to the X axis motion of the XY axis stage.

- Perpendicularity of Motion

Displacement between the Z axis stage and the perpendicular optical breadboard when moving the stage for full travel.

-

Pitch

Maximum angle displacement in the direction of tilt around the axis in the horizontal plane perpendicular to the direction of travel when moving the stage for full travel.

YawMaximum angle displacement in the direction of tilt around the axis in the vertical plane perpendicular to the direction of travel when moving the stage for full travel.

Sensor - Sensor Part Number

Sensor used for the product.

- Limit Sensor

Indicates whether fitted with a limit sensor.

- Origin Sensor

Indicates whether fitted with an origin sensor.

- Proximity Origin Sensor

Indicates whether fitted with a proximity origin sensor.

Motor Specifications - Type

Type of motor.

- Motor Part Number

Part number of motor used for the product.

- Step Angle

Step angle of the motor.

Sensor Specifications - Power Voltage

- Current Consumption

Specifications of the sensor.

- Control Output

- Output Logic

Compatible Driver / Controller

- Compatible Driver

Driver/controller compatible with the product.

- Compatible Controller