Optomechanics

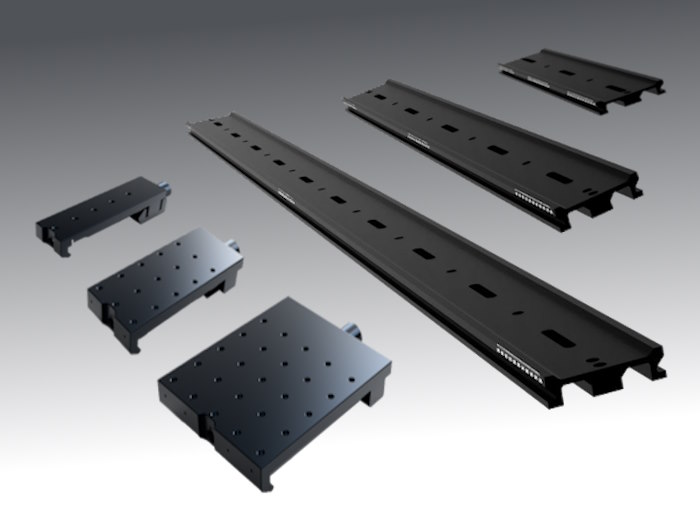

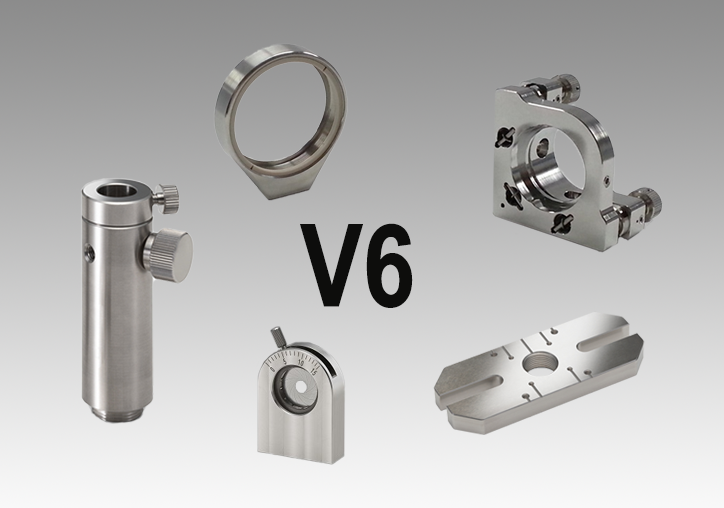

Optomechanics are the mounts, posts, and bases that interface between the optics in your system or experiment and the work surface (e.g. optical table). The main jobs of these components are to 1) hold the optic securely over time, 2) allow positioning the optic coarsely to the optical axis height), and 3) for adjustable mounts, enable fine, high-resolution alignment of the optic to the optical beam. There are unique fixed or adjustable mounts for each different type of optics to be held: mirrors, lenses, filters, prisms, beam splitters, and more. Each mount has different optic mounting methods and different adjustments depending on the type of optics held. For example, most lens mounts hold the optic with a retaining ring contacting the curved optical surface to ensure it is self-centered in the mount. Lens mounts typically have linear adjustments for centering (XY) and focusing (z). Higher-end mounts also include pitch and yaw angular adjustment for more exact alignment. Another important element of optomechanics are the mounting posts and bases. While these are simple parts, they provide an important function for optical mounts - connection to the work surface. There are two main types of mounting posts: fixed-height and height-adjustable. The fixed-height posts provide the most stability simply because there are no moving parts. The most widely used fixed post type is called pedestals due to their wide base. Pedestal posts require a clamping fork to mount to an optical table. Standard post and post holders provide manual height adjustment and are comprised of a post holder and a post that fits inside of the post holder. This arrangement allows for height adjustment as well as rotation adjustment (yaw). Post holders have threaded bottoms to allow mounting directly to the threaded holes on an optical table. While this mounting is convenient, it restricts the location of a post holder to one of the threaded holes on the optical table; note that pedestal posts do not have this limitation due to the fork clamp mounting. For a post holder, this limitation can be overcome with the addition of a mounting base that enables fork-like mounting. Optomechanics are used in one way or another in every optical application or experiment. Although OptoSigma has thousands of these components, if one of our many catalog items does not meet your requirements, send us a request for a custom version.