Search results for: 'manual stages actuators linear stages z axis stages'

-

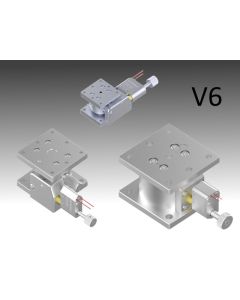

Z-Axis (Vertical Travel) Steel Piezomotor Linear Stages

Z-Axis (Vertical Travel) Steel Piezomotor Linear StagesStarting at $1,447.00

-

Z-Axis (Vertical Travel) Aluminum Piezomotor Linear Stages

Z-Axis (Vertical Travel) Aluminum Piezomotor Linear StagesStarting at $1,090.00

-

Piezo-Assist, Vertical Platform/Horizontal Base, Z Stages

Piezo-Assist, Vertical Platform/Horizontal Base, Z StagesStarting at $980.00

-

Aluminum Crossed Roller Guide Motorized Stage 2 Axis (XY)

Aluminum Crossed Roller Guide Motorized Stage 2 Axis (XY)Starting at $3,050.00