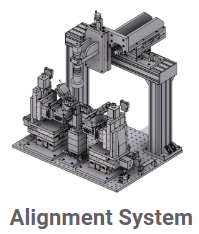

Custom 12 Axis Fiber Aligment System

1. System Overview

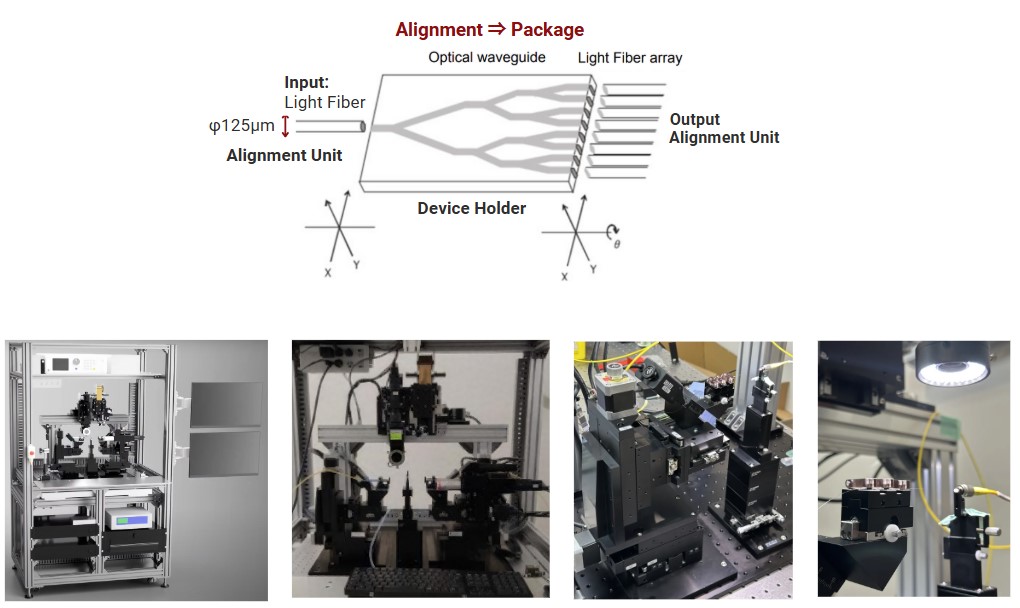

The automatic 12-axis fiber alignment system is designed for precise alignment of optical fibers, optical waveguides, and fiber arrays to ensure efficient optical signal transmission. Configurable for labs or production — balancing speed, accuracy, and repeatability in setups ranging from standard tasks to complex optical integrations.

* Units and Components Available

* Tailored to unique application requirements

Key Features:

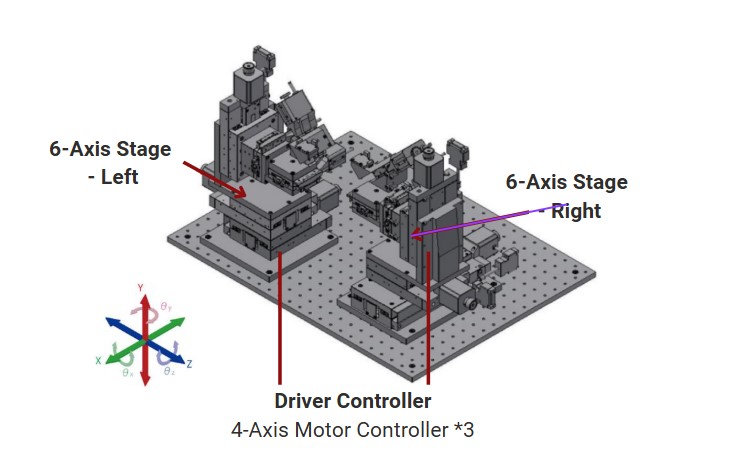

(1)12-Axis Motion Control

Two 6-axis alignment stages (left and right) with combined

linear and rotational motion.

(1)Real-Time Observation & Imaging

Includes a CMOS camera and ring light for live

monitoring.

(1)Precision Alignment Algorithms

Supports raster, spiral, Nelder-Mead, and line

optimization for accurate alignment.

(1)User-Friendly Software

SGAlign software provides real-time control, data storage, and

customizable alignment sequences.

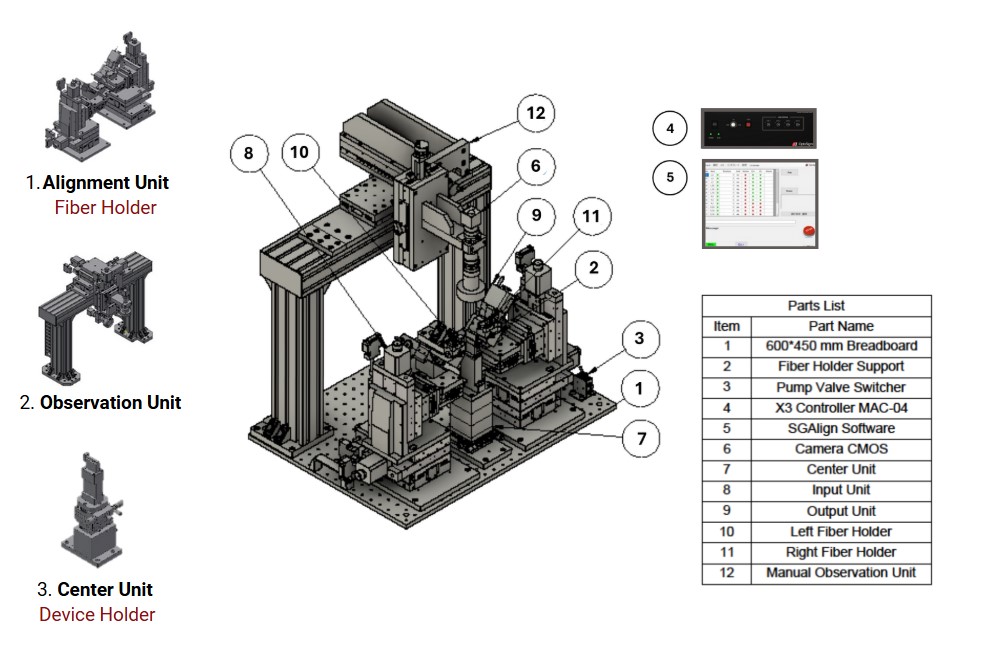

2. Components of Alignment System

2. 1 Alignment Unit

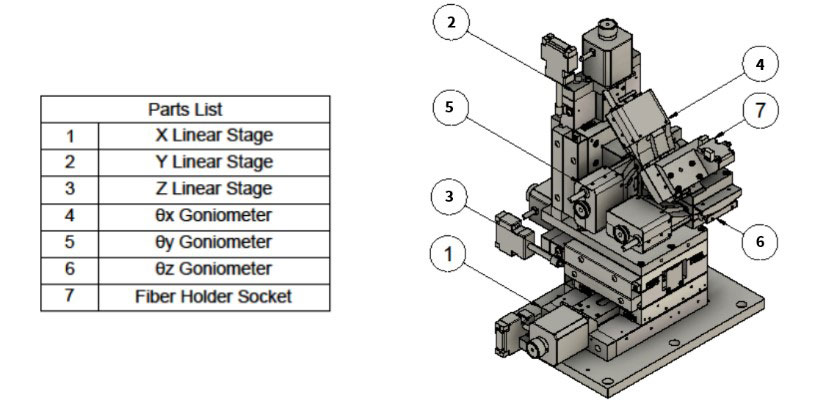

This unit consists of two 6-axis alignment stages for precise movement and positioning of optical fibers and waveguides.

- High-resolution stages ensure precise, rigid, and efficient alignment.

- Magnetic mounts and positioning mechanisms guarantee consistent, repeatable placement.

- Compatible with multiple holders (fiber, rotation, array, etc.) for versatile setups.

System Components

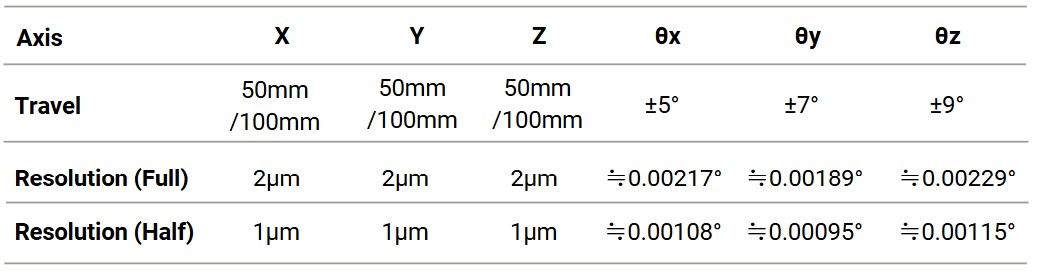

Positioning Specifications

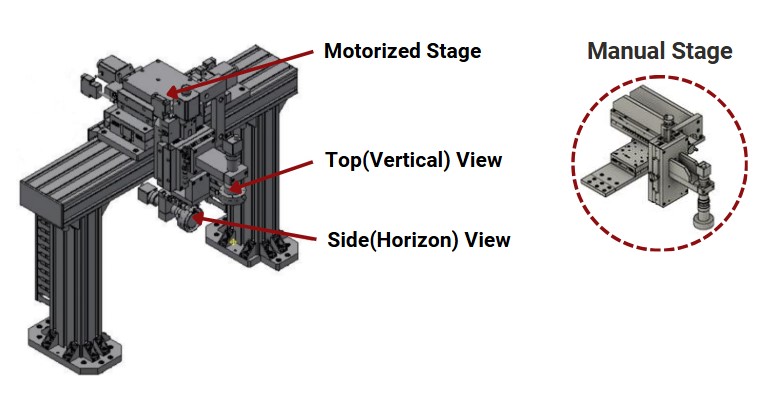

2.2 Observation Unit

This unit enables real-time visualization of the alignment process — waveguide end faces, fiber end faces, devices, etc.

- XYZ Linear Stages for precise movement.

- CMOS Camera for real-time imaging.

- Ring Light for enhanced visibility.

- Vertical Observation: Standard with variable magnification.

- Horizontal Observation: Fixed magnification (1x), optional zoom lens.

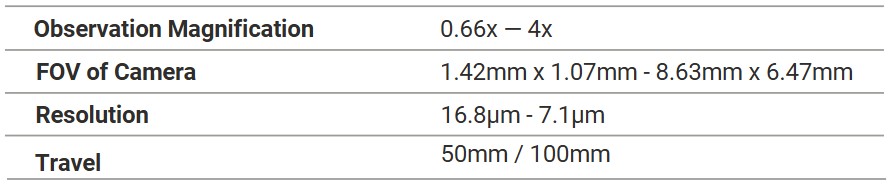

Common Specfications

Vertical Observation Specifications

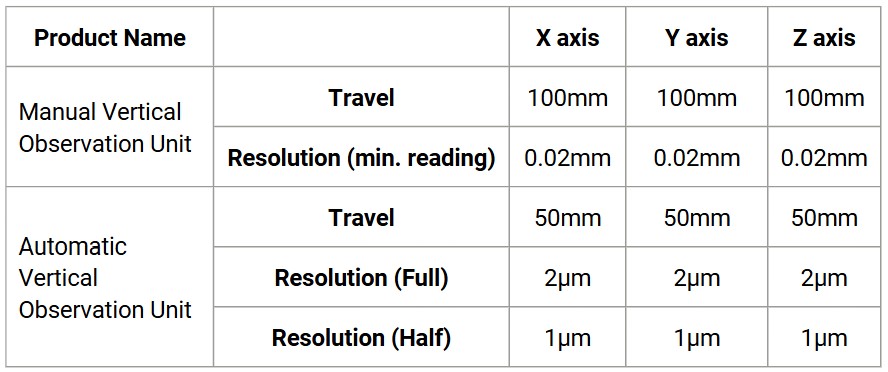

Horizontal Observation Specifications

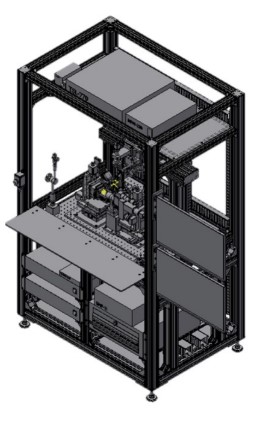

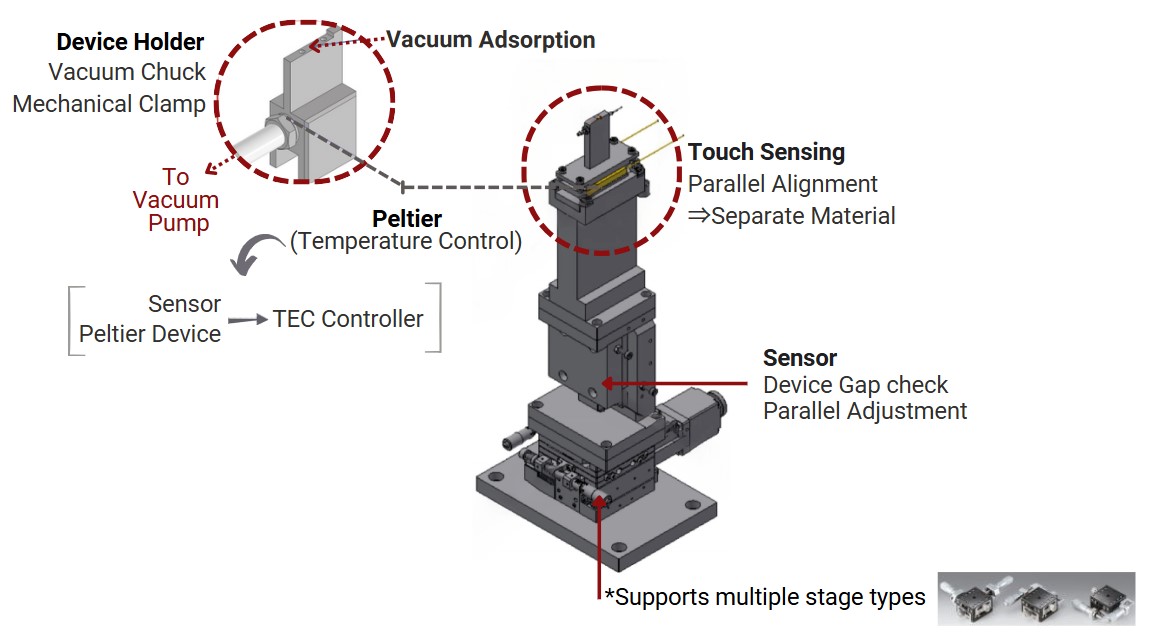

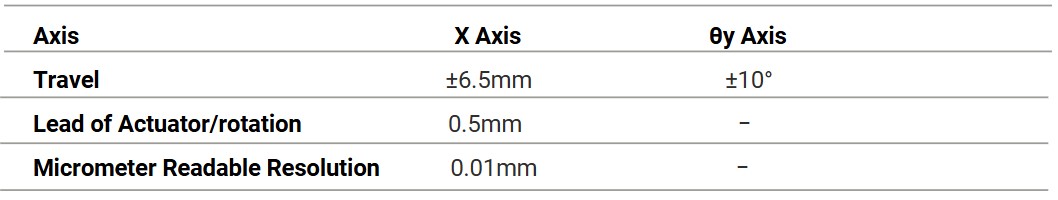

2.3 Center Unit

This unit is designed for precise alignment of 3–8 mm waveguides, serving as the core control hub for the alignment process.

- Sample Fixation: Secure samples via absorption or mechanical clamping.

- Compatible Sizes: Supports 5mm × 5mm and 10mm × 10mm samples.

- Adjustment: Manual 2-axis stage for fine-tuning position and angle.

- Customization: Optional temperature control or contact sensors to meet specific requirements.

CEUT Common Specifications (Manual Stage Part)

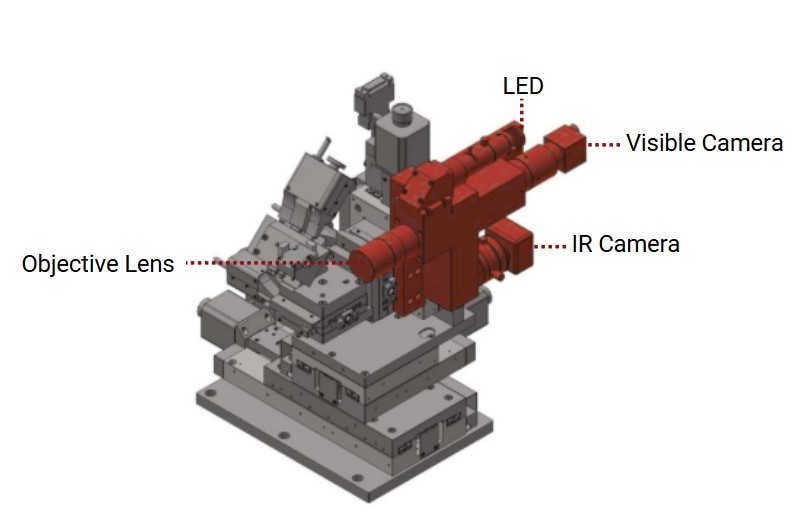

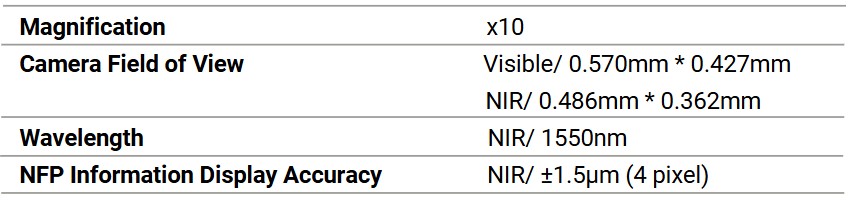

3. NFP Observation Unit / NFP-KIT (Option)

- A versatile observation system with control software for easy and precise measurement of beam diameter (NFP).

- When combined with an automatic alignment unit, it allows for quick adjustments based on luminance values, making it ideal for evaluating optical fibers and waveguides.

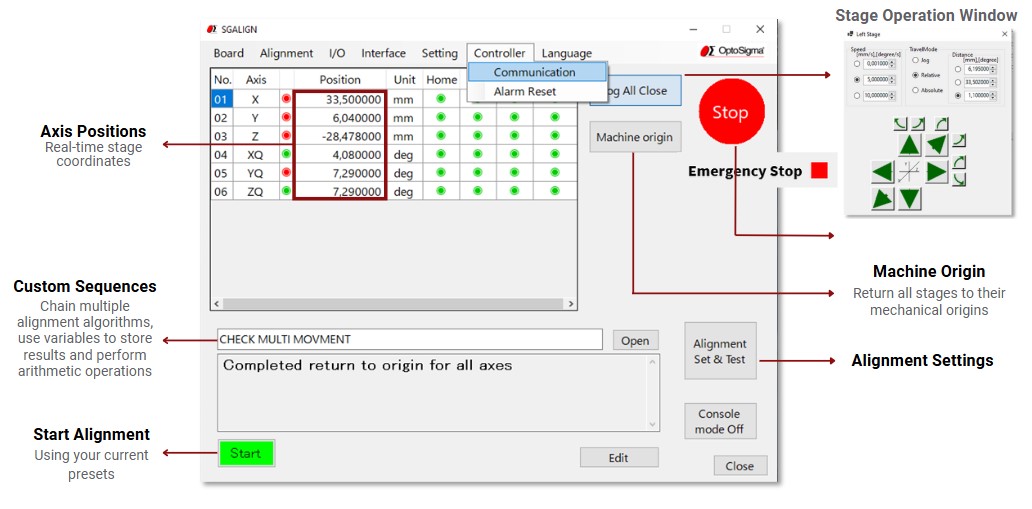

4. Software: SGAlign

The SGAlign software provides an intuitive interface for alignment, offering:

- Real-Time Position Monitoring

- Customizable Alignment Sequences

- Power Measurement and Optimization

- Automated Multi-Step Alignment

5. Applications

- TOSA/ROSA Assembly

- Waveguide Alignment and Testing

- Lens Array and Fiber Array Alignment

- Fiber Alignment and Testing

- Optical Switch Assembly

- CWDM Module Assembly

- Pitch Conversion for Ribbon Fiber

Elevate your optical precision with our customizable alignment solutions.

For tailored support and expert guidance, please email us at: