Manual Linear Translation Stages - Linear Stages

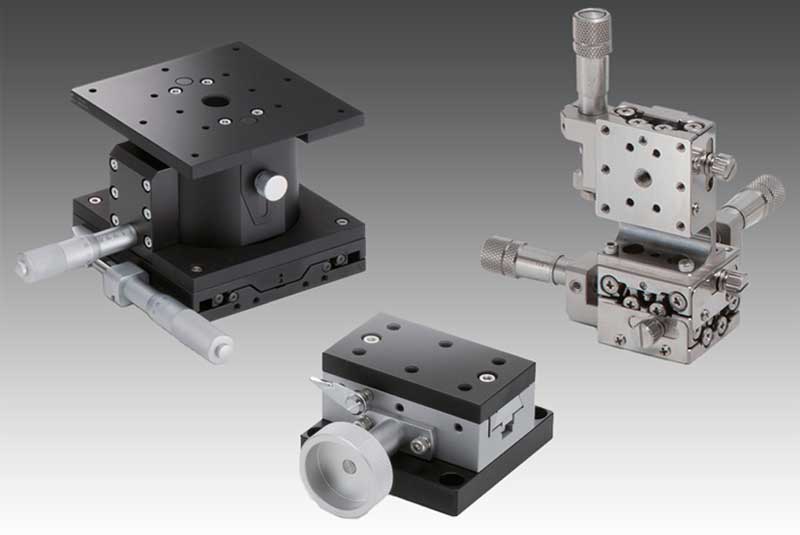

Manual linear translation stages are designed to provide precise, high-resolution travel over any combination of the three linear degrees of freedom. More importantly, however, they constrain any form of movement in the other angular or linear degrees of freedom: pitch, yaw, roll, as well as x-, y-, or z-axis translation. They are frequently used in applications such as microscopy, metrology, optical fiber alignment, optical delay lines, interferometry, or wherever exact linear position is required. Industries that utilize linear stages include research, bio-medical, life sciences, astronomy, metrology, semiconductor, and more. OptoSigma offers the largest selection of linear translation stages to meet virtually any application. For example, we have the most bearing options of any manufacturer, including EXC™ precision bearing, ball bearing, crossed-roller bearing, linear bearing, and dovetail bearing. Additionally, they are available in materials ranging from brass, aluminum, tool steel and stainless steel. If one of our many catalog stages does not meet your requirements, send us a request for a custom stage. OptoSigma is, after all, the industry leader in translation stages.

Linear Stages Guide

What is a Manual Linear Translation Stage?

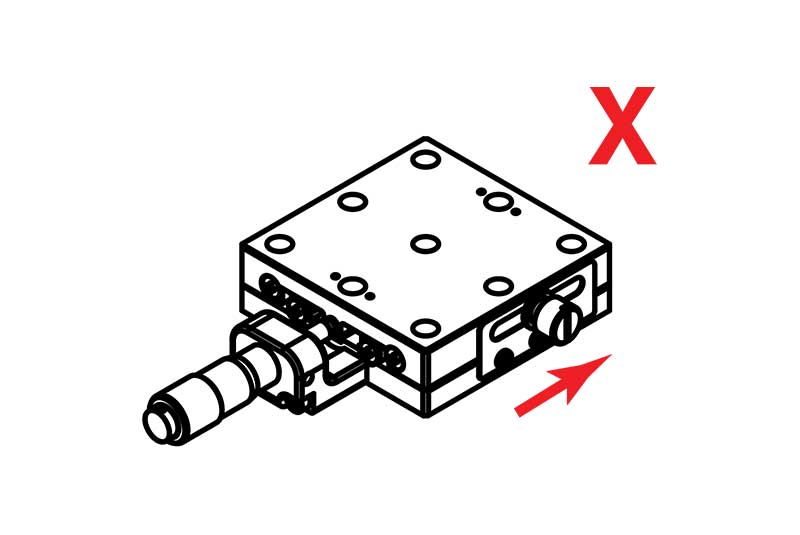

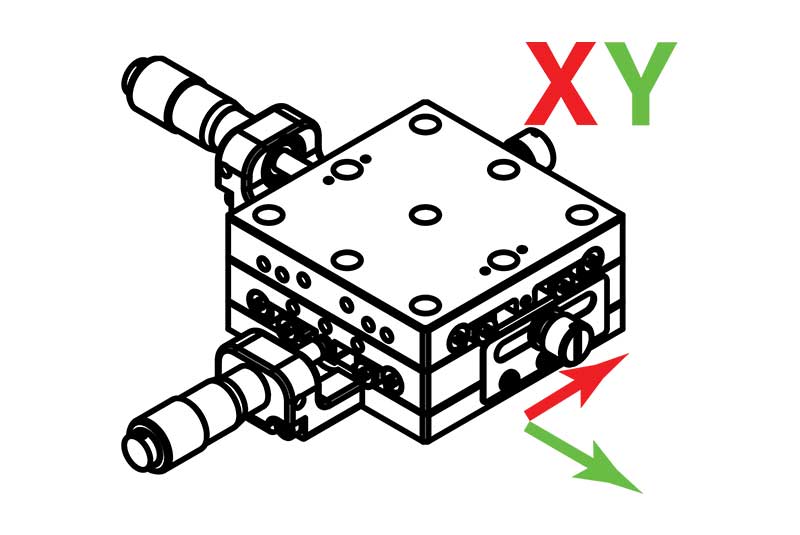

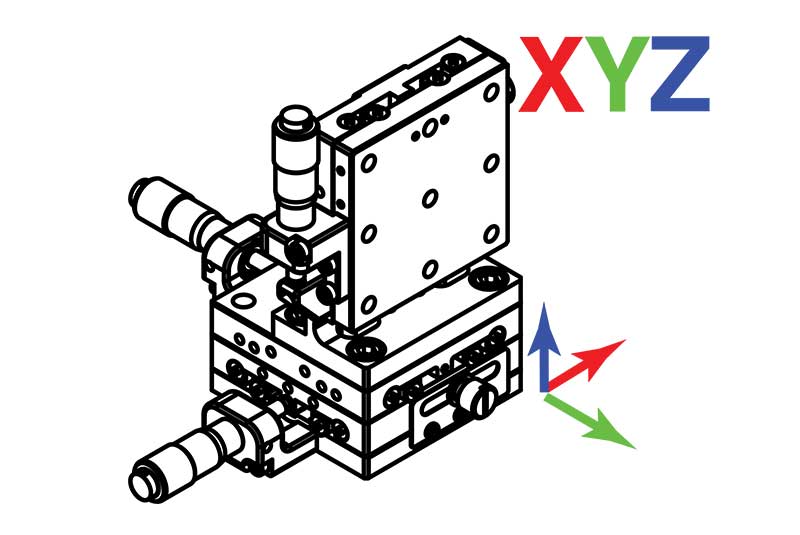

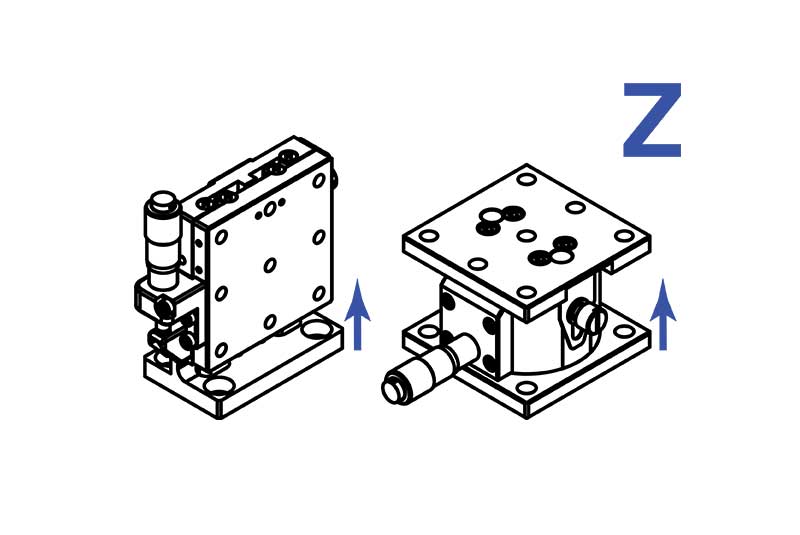

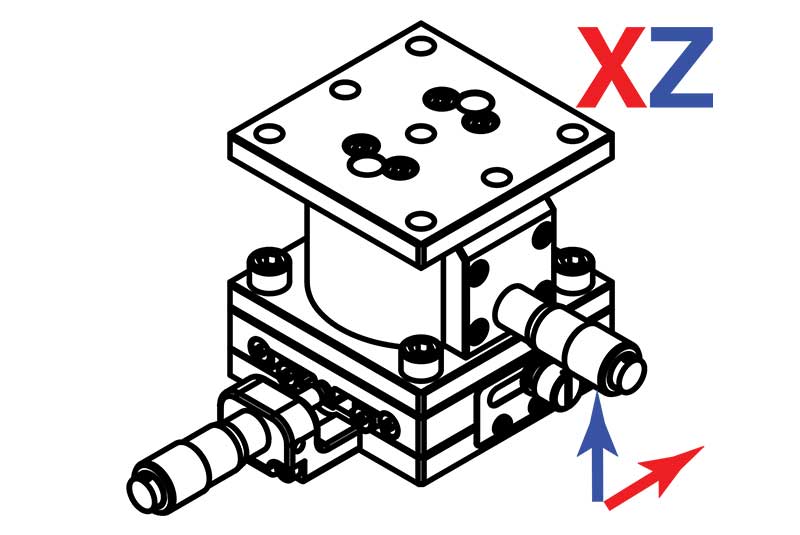

It is a precision device that allows controlled linear motion along one or more axes (X, Y, Z).

- It consists of a movable top plate and a fixed base, connected by a guiding mechanism and adjusted manually using micrometers heads or fine-pitch screws.

- This design enables accurate, repeatable positioning for applications requiring precise linear adjustment.

What are the Main Types of Linear Stages?

How to choose the Right Stage?

Key factors when selecting a linear stage include:

- Load capacity

- Travel range

- Positioning and repeatability accuracy

- Material (aluminum/ steel/ stainless steel) → Affecting stiffness, durability, and cost

1. Crossed-Roller Guide Method (TAM, TAMC Series)

- Rollers in line contact within a V-groove rail deliver excellent stiffness.

- This design ensures low friction and virtually eliminates differential slip, making it ideal for ultra-fine motion control.

Key Features

- High precision and rigidity for optical alignment

- Lightweight aluminum body reduces system load

2. Dovetail Slide Method (TASB/TAR Series)

- Uses a face-contact dovetail mechanism.

- Not suitable for fine adjustments due to higher friction, but reliable for basic positioning.

Key Features

- Low-cost, simple structure

- Stable and robust

- Compact size for tight-space installations

3. Ball Guide Method (TSD/TSDH/TSDT/TSDS Series)

Key Features

- High Load Capacity & Stiffness

- High Durability

- High Precision

A four-contact-point R-groove structure offers stable support and 13× greater stiffness than V-groove designs (Fig. 1). It distributes load efficiently in high-contact directions, ensuring mechanical stability.

Pressure on the R-groove surface is dispersed (Fig. 2), reducing internal stress and preventing metal fatigue or wear—ideal for long-term use and minimal maintenance.

Top and bottom plates are simultaneously machined using a custom jig to minimize deviation.This ensures straightness ≤ 0.7 μm (Fig. 3), maintaining precision as if the ball were in place during machining.

Comparison of thickness of a Crossed Roller Stage and a Ball Guide Stage

* The TSDT series further reduces the stage thickness to 10mm.

4. Applications

- Laser beam alignment

- Optical delay lines

- Microscope sample positioning

- Metrology and precision assembly

- Semiconductor equipment

- Research and laboratory systems

- Fine adjustment in interferometers and optical fibers

Need a Custom Solution?

Contact our technical team for expert support and tailored recommendations.