Search results for: 'manual stages actuators motorized motion control motorized actuators'

-

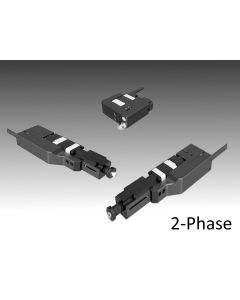

Actuator for Objective Lenses (Stepper motor type)

Actuator for Objective Lenses (Stepper motor type)Starting at €2,706.00

-

Two Channel Controller for RMH Encoded DC Actuators

Two Channel Controller for RMH Encoded DC ActuatorsStarting at €753.80