Fused Bundle Fiber

Custom-made(FBF)

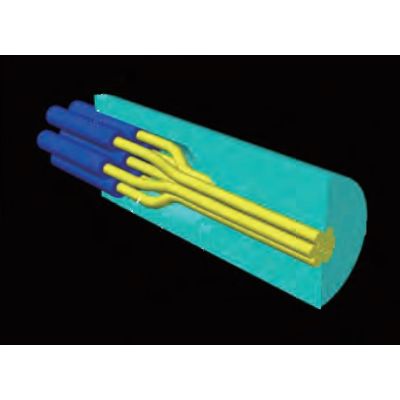

A fused bundle fiber that uses jacketing technology to bundle multiple optical fibers without the use of adhesive.

The heat source that is used when constructing fused bundle fiber is the same as jacketing technology: discharge, resistive-heating furnace, or microtorch. The heat source used for bundling differs to suit the outer dimensions. This technology does not use adhesive, and with excellent heat-resistance characteristics suited to high-temperature environments.

Optical fibers can also be bundled in any desired layout.

The heat source that is used when constructing fused bundle fiber is the same as jacketing technology: discharge, resistive-heating furnace, or microtorch. The heat source used for bundling differs to suit the outer dimensions. This technology does not use adhesive, and with excellent heat-resistance characteristics suited to high-temperature environments.

Optical fibers can also be bundled in any desired layout.

◦In addition to a hexagonal packed layout, optical fibers can be arranged in any desired layout using dummy rods

◦Adjacent optical fibers are kept in place using hot-melt without the use of adhesive, giving it a high level of heat-resistance and reliability.

◦AR (non-reflective) and other coatings can be applied to the optical fiber ends.

◦Adjacent optical fibers are kept in place using hot-melt without the use of adhesive, giving it a high level of heat-resistance and reliability.

◦AR (non-reflective) and other coatings can be applied to the optical fiber ends.

| Name | Fused Bundle Fiber |

|---|---|

| Weight | 0.0050kgs |

| Guide | - |

| Attention |

|

Out of stock

SKU

Custom-made(FBF)

A fused bundle fiber that uses jacketing technology to bundle multiple optical fibers without the use of adhesive.

The heat source that is used when constructing fused bundle fiber is the same as jacketing technology: discharge, resistive-heating furnace, or microtorch. The heat source used for bundling differs to suit the outer dimensions. This technology does not use adhesive, and with excellent heat-resistance characteristics suited to high-temperature environments.

Optical fibers can also be bundled in any desired layout.

The heat source that is used when constructing fused bundle fiber is the same as jacketing technology: discharge, resistive-heating furnace, or microtorch. The heat source used for bundling differs to suit the outer dimensions. This technology does not use adhesive, and with excellent heat-resistance characteristics suited to high-temperature environments.

Optical fibers can also be bundled in any desired layout.